Inventory Management

Grinding

Heat Treating

Product Testing Assembly

Oxy-Fuel & Plasma Burning

Welding

Painting / Coating

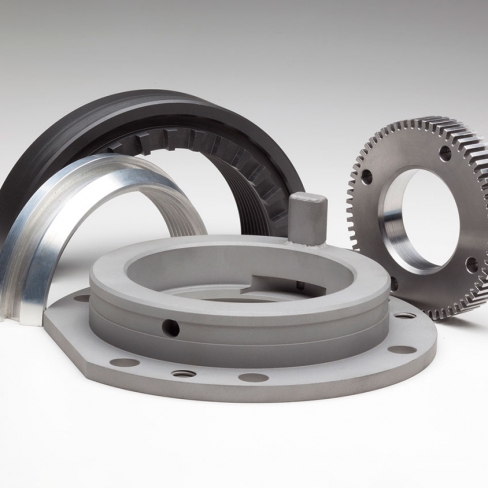

Turnkey Machining and Manufacturing Services

Complete Machining, Fabricating, and Assembly

In addition to our precision machining capabilities, LAMJEN provides turnkey solutions for components that require fabrication, welding, assembly, and packaging. Our fabrication capabilities include large industrial fabrication and fit up, and welding services. LAMJEN, part of Custom Group Industries, is a single-source manufacturing partner offering not only extensive machining capabilities but an array of secondary, value-added services for fully assembled machined components made to exact specifications.

Gallery

Turnkey Machining and Finishing Solutions

LAMJEN facilitates a variety of processes and services to fabricate components according to exact customer requirements, specifications, and fully assemble, package and ship for a turnkey solution. Our secondary services include:

Inventory Management

LAMJEN offers inventory management solutions for the management of raw materials, components, and finished products, as well as warehousing and processing of these items. Our services include assistance with:

- Order management

- Inventory control

- Inventory forecasting

Oxy-Fuel & Plasma Burning

LAMJEN offers plasma and oxy fuel cutting for steel and other alloys up to 12” thick through our sister companies within Custom Group Industries. The dual plasma and oxy burners cut steel to size to be machined and assembled into kitted soleplate packages. Our plasma cutting capabilities position Custom Group Industries as a leader in large-scale metal fabrications.

Grinding

Blanchard or Rotary Grinding removes large amounts of surface stock providing excellent flatness and parallelism with a quality finish. Our rotary grinding facilities include a 72” rotary table accommodating an 84” swing and 22” height. Our Supertec horizontal surface grinder provides precision flatness and parallelism as well as a smooth finish. Custom Group Industries’ new surface grinder accommodates parts as large as 80 inches in width, 118 inches in length and 18 inches in height.

Welding

Manufacturing mid to large-scale parts and components from steel plate requires both facilities designed specifically to produce those parts, and a team of highly skilled craftsmen. Through Custom Group Industries, our combination of burn tables, precision fit-up structures, certified welders, and robotic welding capabilities allows us to produce large metal fabricated components. Our process is ISO-9001:2015 certified and we have AWS, ASME, NADCAP, and TPG certified welders to ensure the highest quality standards. Within Custom Group Industries, we are well-versed in all forms of welding including:

- Tungsten Inert Gas (Tig)

- GMAW (Mig)

- FCAW (Flux Core)

- SAW (Sub Arc Welding)

- Welding overlays – Corrosion resistant welding (Inconel)

Heat Treating

For machined parts that require superior ductility, strength, hardness, and toughness, heat treatment may be required. LAMJEN facilitates common heat treatments for CNC machined parts so that the parts are already treated before moving on to the next manufacturing phase, or shipment.

Painting / Coating

Our coating application specialists hold a Level II certification from the SSPC (The Society for Protective Coatings), the highest certification they offer. This makes our professionals the best in the region at what they do. Custom Group Industries uses environmentally-friendly coatings and paints in all of our spray booths, powder coating, and finishing operations. The coatings used must meet strict environmental guidelines.

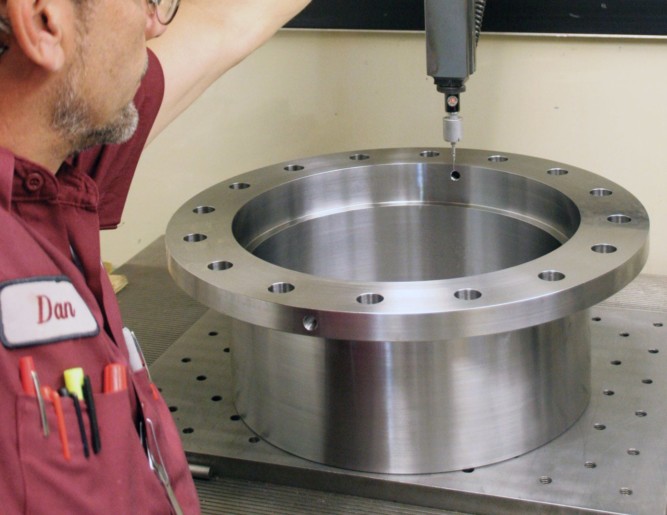

Product Testing Assembly

LAMJEN offers full product assembly and shipping as needed, with detailed instructions and documentation for reassembly. We are able to deliver complete, ready to use products when needed. We are also able to perform product testing for some parts and components for adherence to specifications upon request. LAMJEN offers these value-added services for complete turn-key parts and solutions.

Industries Served

Experienced In...

Breaking Into...

Related News

CNC Machine Shop with Fabrication Capabilities

Casting. Cutting. Drawing. Folding. Forging. Extrusions. Machining. Punching. Shearing. Stamping. Welding. What does it mean to have all of these processes available from one machining team? A one-stop CNC fabricating…

Machine Shop with Inventory Management Capabilities | Part Stocking & Warehousing

Choosing a CNC machine shop might seem like a shot in the dark, like the old days of turning to the right page of the phone book, then blindly selecting…

LAMJEN has the Equipment Needed to Serve as Your Tight Tolerance Machine Shop

LAMJEN has the Equipment Needed to Serve as Your Tight Tolerance Machine Shop With five decades of experience in business and a suite of over a dozen advanced CNC machines…

CNC Machine Shop QMS (Quality Management System)

A CNC Shop QMS (Quality Management System) Ensures Production Quality Even the most advanced and modern CNC machines require experienced human oversite to ensure the quality of their output precisely…

Our New MB-80V CAT50 Big Plus Bridge Mill by Okuma

Utilize our MB-80V CAT50 Big Plus Bridge Mill for Your Next Custom Precision Machined Part A Machining Shop in Erie, PA that is Always Enhancing Capabilities LAMJEN is a machining…

CNC Machine Shop with Fabrication Capabilities

Casting. Cutting. Drawing. Folding. Forging. Extrusions. Machining. Punching. Shearing. Stamping. Welding. What does it mean to have all of these processes available from one machining team? A one-stop CNC fabricating…

Machine Shop with Inventory Management Capabilities | Part Stocking & Warehousing

Choosing a CNC machine shop might seem like a shot in the dark, like the old days of turning to the right page of the phone book, then blindly selecting…

Large Part CNC Turning Erie, PA

For large part CNC (computer numerical control) turning in Erie, Pennsylvania, LAMJEN has the experience and technology to realize your project fully. Among our shop services, we offer CNC lathing…

Keeping CNC Machining Costs Low & Turnaround Quick

Keeping CNC machining costs low can be difficult, especially if you’re unsure of the elements of machining that take the most work and time to begin with. Fortunately, there are…

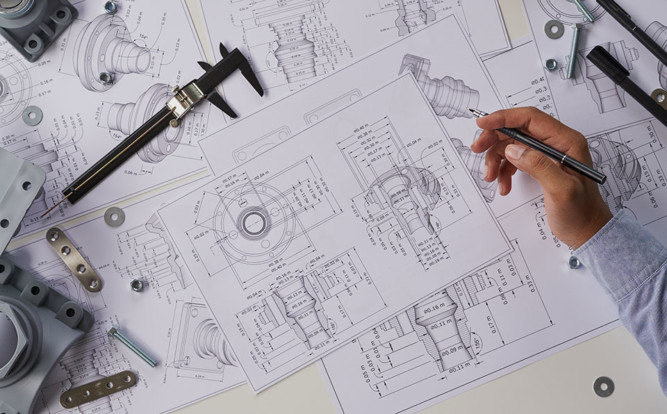

Custom Precision Machining & Part Design: From Prototyping to Production

As many customers likely know, it is generally faster and cheaper to find a machine shop that is capable of handling their project from beginning to end as opposed to…