CNC Machine Shop with ISO-9001:2015 Certification by NQA in PA

Quality Control System

Quality Assurance Program

Contract CNC Machining Quality Assurance Systems

Commitment to Quality

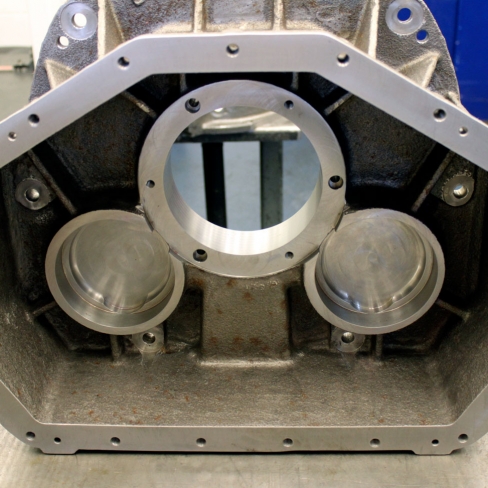

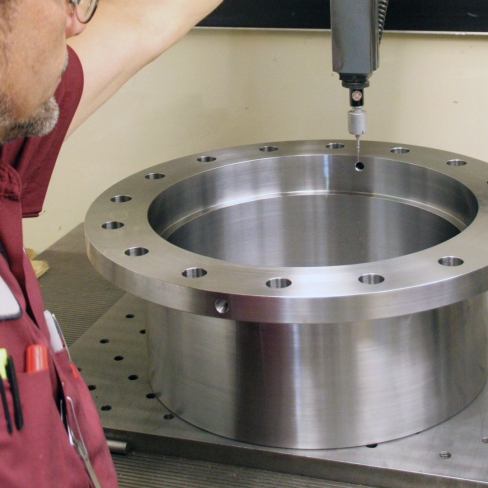

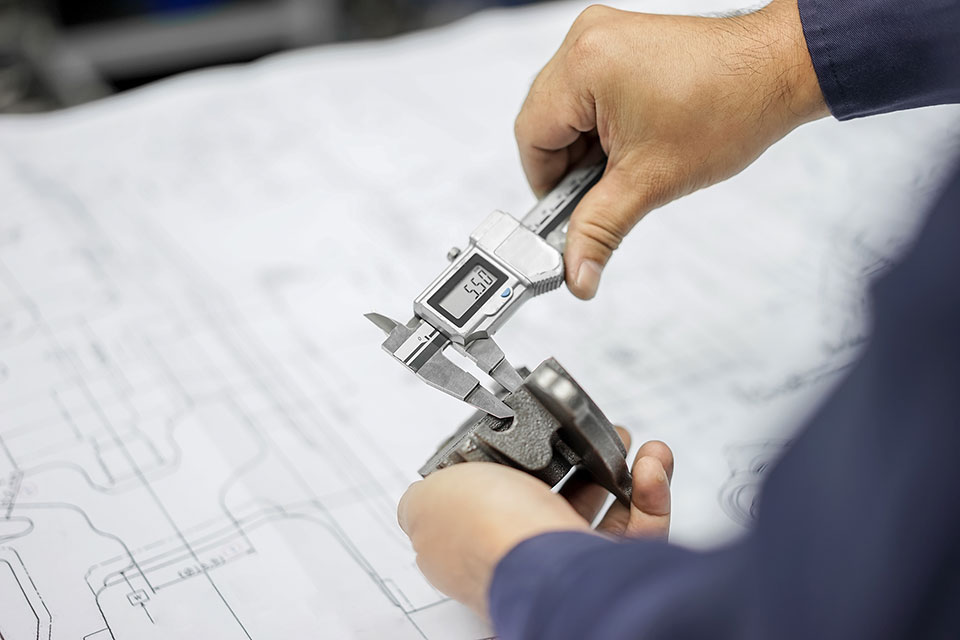

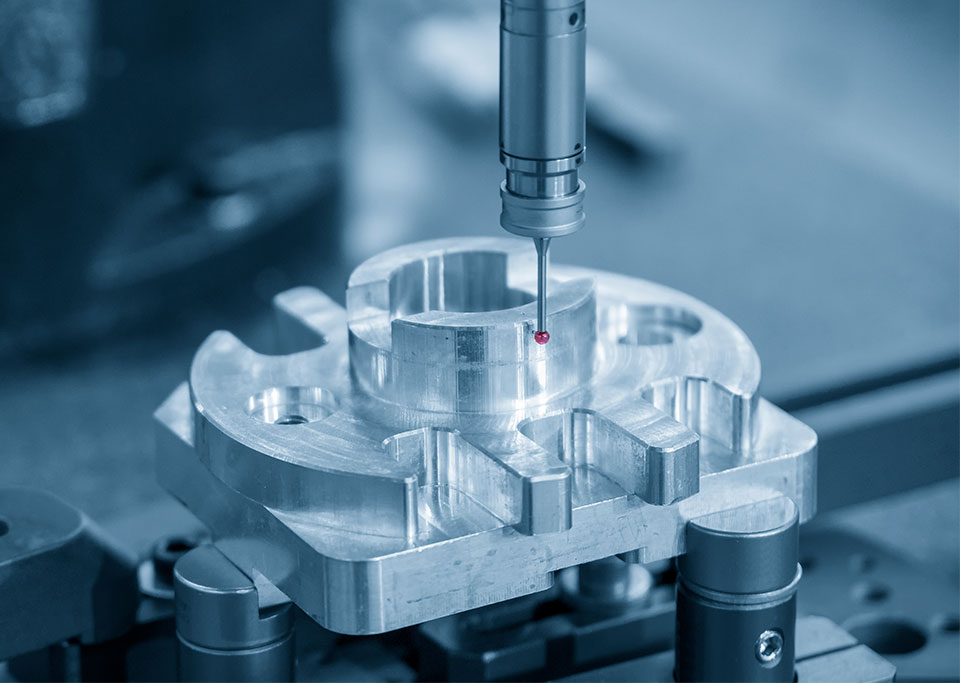

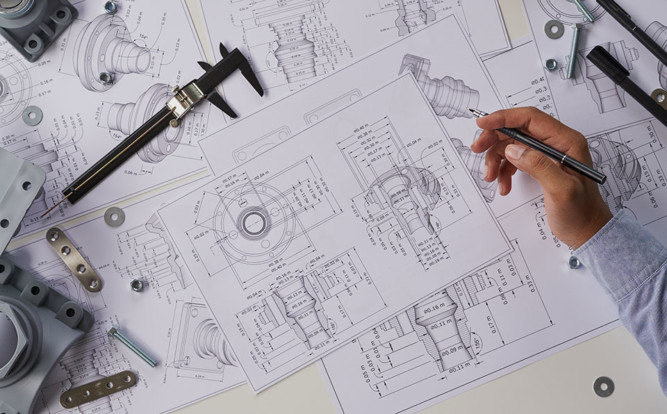

LAMJEN is committed to delivering high-quality machined products that fully meet customer expectations and regulatory standards. Our quality control department is equipped with CMM capabilities, Faro Gauge, comparator, surface plates and appropriate gauging and inspection tooling to ensure dimensional accuracy. Our comprehensive quality assurance program adheres to ISO-9001:2015 standards and other applicable requirements while focusing on the continuous improvement of our quality system. Our comprehensive quality assurance program, backed by our ISO-9001:2015 certification by NQA enables us to compete successfully worldwide.

We are focused on building valued customer relationships and developing long-lasting partnerships. Our complete realization of customers’ needs makes LAMJEN a trusted, reliable source for precision machined products.

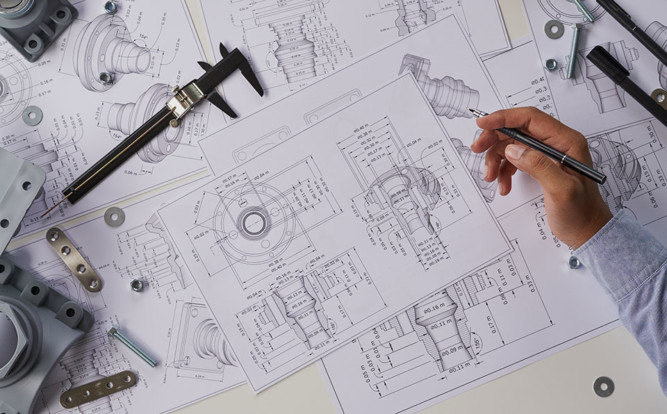

Gallery

Quality Control System for Precision Machined Components

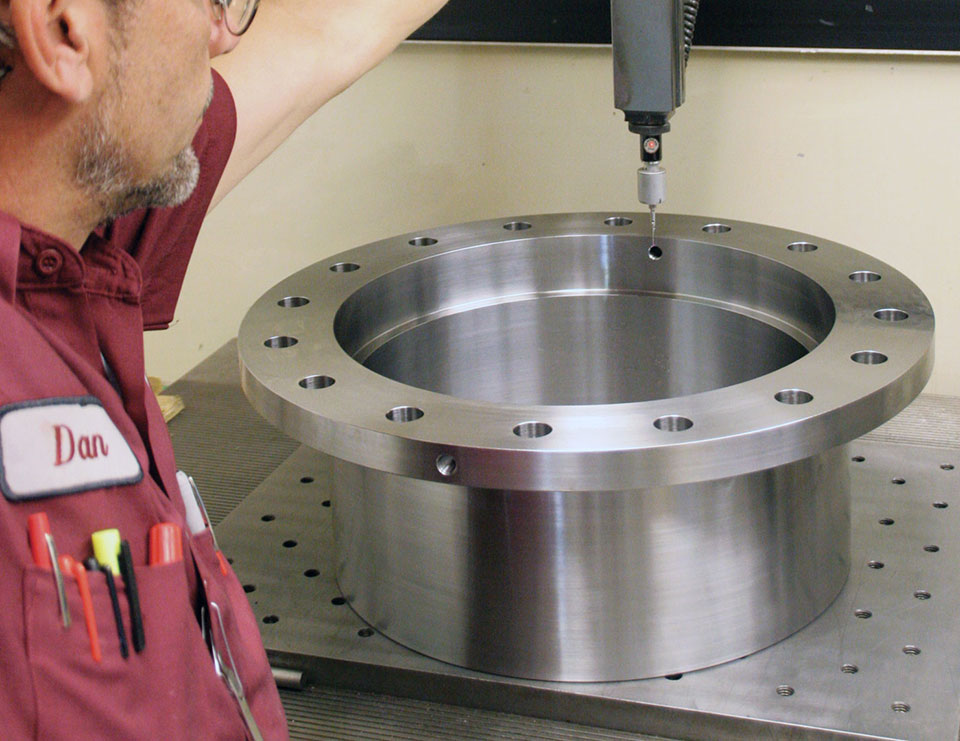

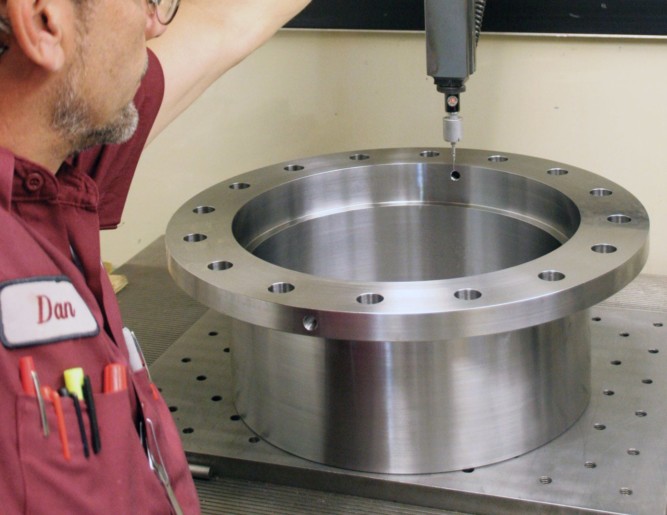

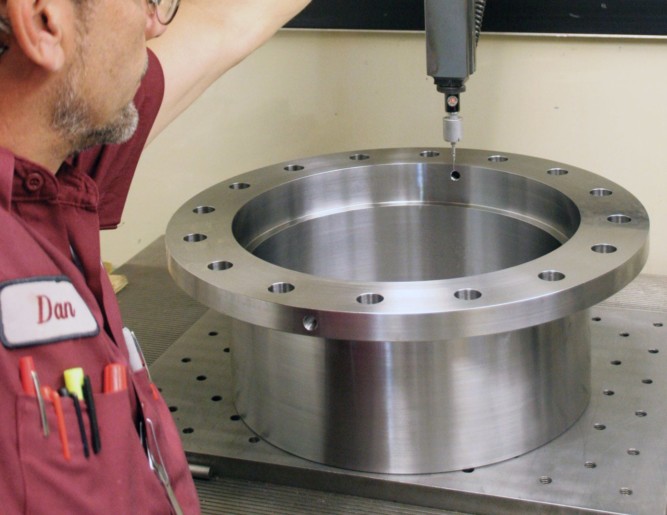

LAMJEN takes pride in its advanced standard of quality. Our certification to the ISO-9001:2015 standard permits LAMJEN to be officially recognized on a worldwide scale for our ability to manufacture products with a consistently high level of quality. LAMJEN provides top quality products manufactured to our customers’ specifications. The Quality Assurance Department provides control of materials and finished products through monitoring of operations, inspection of goods, and recording of associated documentation. Services such as First Article Inspection and PPAP are available upon request.

Significant Inspection Equipment

- Brown & Sharpe Programmable CMM – Capable of utilizing customer supplied models for programming. Table size 40″ X 56″ X 28″

- Faro Gauge fully portable CMM – Fully articulating arm with an inspection radius of 24 inches to allow inspection of parts in one setup

- S-T Industries 30″ Optical Comparator

- Surface plates with up to 4’x 4′ capacity

ISO-9001:2015 Certified by NQA Quality Assurance Program

The raw materials and precision machined products are controlled by an in-house quality assurance department dedicated to monitoring the operations, inspecting the finished product, and keeping a verifiable record to ensure complete traceability for each product lot. LAMJEN maintains a successful quality assurance program by monitoring production through our comprehensive quality process:

- Focus on customer satisfaction

- Controlled Documentation System (Procedures and Work Instructions)

- Continuous Improvement

- Corrective Action Program

- Regular Internal Auditing of The Quality System

- Ongoing Training to Updated Procedures

- Customer Delivery Tracking System

- Vendor/Subcontractor Quality Evaluation System

Lamjen provides top quality products manufactured to our customers’ specifications. Incidents of non-conformity are documented through Corrective Action Reports to determine Root Cause and the appropriate Corrective Actions to prevent re-occurrence. In pursuit of continuous improvement, internal audits are conducted, and improvement projects are implemented to prevent potential risks.

Industries Served

Experienced In...

Breaking Into...

Related News

CNC Machine Shop QMS (Quality Management System)

A CNC Shop QMS (Quality Management System) Ensures Production Quality Even the most advanced and modern CNC machines require experienced human oversite to ensure the quality of their output precisely…

Custom Precision Machining & Part Design: From Prototyping to Production

As many customers likely know, it is generally faster and cheaper to find a machine shop that is capable of handling their project from beginning to end as opposed to…

LAMJEN has the Equipment Needed to Serve as Your Tight Tolerance Machine Shop

LAMJEN has the Equipment Needed to Serve as Your Tight Tolerance Machine Shop With five decades of experience in business and a suite of over a dozen advanced CNC machines…

CNC Machine Shop QMS (Quality Management System)

A CNC Shop QMS (Quality Management System) Ensures Production Quality Even the most advanced and modern CNC machines require experienced human oversite to ensure the quality of their output precisely…

Our New MB-80V CAT50 Big Plus Bridge Mill by Okuma

Utilize our MB-80V CAT50 Big Plus Bridge Mill for Your Next Custom Precision Machined Part A Machining Shop in Erie, PA that is Always Enhancing Capabilities LAMJEN is a machining…

CNC Machine Shop with Fabrication Capabilities

Casting. Cutting. Drawing. Folding. Forging. Extrusions. Machining. Punching. Shearing. Stamping. Welding. What does it mean to have all of these processes available from one machining team? A one-stop CNC fabricating…

Machine Shop with Inventory Management Capabilities | Part Stocking & Warehousing

Choosing a CNC machine shop might seem like a shot in the dark, like the old days of turning to the right page of the phone book, then blindly selecting…

Large Part CNC Turning Erie, PA

For large part CNC (computer numerical control) turning in Erie, Pennsylvania, LAMJEN has the experience and technology to realize your project fully. Among our shop services, we offer CNC lathing…

Keeping CNC Machining Costs Low & Turnaround Quick

Keeping CNC machining costs low can be difficult, especially if you’re unsure of the elements of machining that take the most work and time to begin with. Fortunately, there are…

Custom Precision Machining & Part Design: From Prototyping to Production

As many customers likely know, it is generally faster and cheaper to find a machine shop that is capable of handling their project from beginning to end as opposed to…